Colours and Coatings

We point out that colour deviations in all color tones within certain tolerance limits must be accepted when using different material batches. In case of any doubt we always recommend to have the ordered material produced from one material batch. Montana Building Systems Ltd. shall not be liable for colour differences between products from Montana amongst one another and between products from Montana and those of other manufacturers. This applies for all colors and all pre-painted products. When various products or coatings are installed with one another and need to have the same color tone, then a selection must be made.

Metallised and transparent color systems require particular attention. When using these types of coatings, Montana Building Systems Ltd. recommends taking into account the façade areas when specifying the application quantities in the order so that they can be finished within one batch of material. Métallisé versions are provided with arrow markings on the rear side or on the protective film in order to clearly indicate the structure direction for perfect installation.

PROPERTIES

The layer thickness is 15 μm, while the hot-dipped galvanised carrier material is based on zinc or MagicZinc® with good corrosion resistance. Due to its light colour tone, it achieves optimum light reflection and thus contributes to a reduction in lighting costs.

COLOUR COLLECTION

ADVANTAGES

- Efficient and durable product for indoor applications that has as long a service life as the building itself under normal conditions without stress.

PROPERTIES

The coating consists of a substrate of galvanized steel with a smooth coating based on polyester resin with a layer thickness of 25 μm. The rear side is provided with a light-coloured coating of approx. 10 μm.

COLOUR COLLECTION

ADVANTAGES

- Smooth polyester coating

- Available in the commonest roof and façade colour tones

The polyester coating 35 μm is an economical product for standard roof and façade applications

for low to medium atmospheric exposure. Use in highly marine and industrial environments is not recommended.

PROPERTIES

The creative all-rounder for indoor and outdoor use. The coating consists of a substrate of galvanized steel with a smooth coating

based on polyester resin with a layer thickness of 35 μm. The rear side is provided with a light-coloured coating of approx. 10 μm.

COLOUR COLLECTION

ADVANTAGES

- Polyester coating 35 μm

- Very good corrosion resistance

- Very good UV resistance

aesthetic appearance and a long service life.

PROPERTIES

SDP 50 μm is a coating based on a 25 μm thick high-build primer and a 25 μm thick top coat of high-performance polymer with

a closed surface. In addition to a lasting decorative appearance, the SDP 50 coating meets all the usual mechanical corrosion

requirements and has very good resistance to solvents, chemicals and UV radiation.

COLOUR COLLECTION

ADVANTAGES

- Meets the highest corrosion protection class RC5+

- Hot-dip galvanized support material in accordance with EN 10346:2015

- Maximum corrosion protection, even at the cut edges

- Meets the requirements of the highest UV resistance class RUV4 of EN 10169

- Top performance in terms of durability and aesthetic longevity

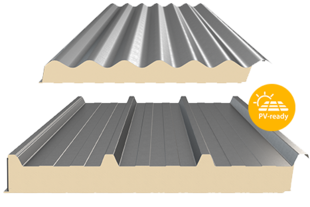

- Is suitable for use under photovoltaic (PV) modules; the warranty period remains unaffected

- High-quality back coating for optimum foam adhesion for sandwich elements.

PROPERTIES

The layer thickness is 65 μm and the carrier material is Galvalloy, which consists of a special mixture of 95 % zinc (Zn) and 5 % aluminium (Al). In comparison with conventional hot-dipped galvanised carrier materials, this composition offers not only increased barrier protection, but also a cathodic protective effect for unrivalled corrosion protection – even at the cutting edges.

COLOUR COLLECTION

ADVANTAGES

- Fulfils the highest corrosion protection class RC5 of EN 10169

- Maximum corrosion protection even at the cutting edges

- Fulfils the requirements of the highest UV resistance class RUV4 of EN 10169

- Best performance as regards wear resistance and aesthetic durability

- Unique gloss due to the unstructured arrangement of metal pigments

- Rear-side branding for complete traceability

- Has excellent resistance to scratching due to the addition of hard polyamide particles in the outside layer

- Up to 40 years Confidex® guarantee services

- Suitable for use under photovoltaic (PV) modules; the warranty period remains unaffected

PROPERTIES

Compared to anodised aluminium, the matt anodised coating with steel carrier material impresses with maximum flexibility in deformation (3 T bending without cracks), as well as with the avoidance of unwanted colour differences (within the same batch). Of course, the matt anodised coating also offers excellent UV resistance and optimum corrosion protection.

COLOUR COLLECTION

ADVANTAGES

- 2-layer 35 μm

- Fulfils the requirements of the highest UV resistance class RUV4 of EN 10169

PROPERTIES

PVDF 25 μm is a coating based on polyvinyl difluoride and other binders. In addition to a sustainable decorative appearance, the PDVF coatings meet all common mechanical corrosion requirements and exhibit good resistance to solvents, chemicals and UV radiation.

COLOUR COLLECTION - on request

ADVANTAGES

- Smooth 25 μm coating with good colour fastness and gloss retention

- Good resistance to corrosion and UV radiation

PROPERTIES

This product is suitable for demanding indoor applications, such as swimming pools, sewage treatment plants and biogas plants. Colorcoat HPS200 Ultra® is produced as standard with a protective coating on the rear side. This version is suitable for building envelopes that are exposed to aggressive and particularly demanding internal and external atmospheres.

COLOUR COLLECTION - on request

ADVANTAGES

- Maximum corrosion protection even at the cutting edges

- Fulfils the requirements of the highest UV resistance class RUV4 of EN 10169

- Best performance as regards wear resistance and aesthetic durability

- Recyclable

- Up to 40 years Confidex® guarantee services

- Suitable for use under photovoltaic (PV) modules; the warranty period remains unaffected

PROPERTIES

COLORFARM® is a pre-painted steel with very high corrosion resistance and a 35 μm thick coating. The rear side is provided with a protective coating. For that reason, COLORFARM® is very suitable for use on the inside of agricultural buildings that are heavily exposed to ammonia.

COLOUR COLLECTION

ADVANTAGES

- 35 μm coating; developed to ensure the best possible chemical resistance

-

Hot-dipped galvanised steel, manufactured according to EN 10346:2009

-

15-year warranty on functionality on the inside of the room

-

Meets the highest resistance class CPI5 according to EN 10169:2010 for indoor applications